It is some time now that, in the rare occasions I have to listen to some music with my hifi system, I choose to play a vinyl record on my old Thorens TD-165 instead of a CD. It’s not about what kind of music to listen to, it’s just about listening to a vinyl record: unfolding it, cleaning it, letting the stylus descend, they all are gestures of a time gone but that are part of a relaxing ritual which is typical of using a turntable. Playing a CD would be faster, no time lost, but it would be no different from the frantic life of today’s world. What I’m looking for is an escape from this stress: we’re always on the run, so when I have some time to spend listening to music, I’d like to take a break from the frenzy. Preparing to listening to a vinyl record takes time – and this is just the point.

It is some time now that, in the rare occasions I have to listen to some music with my hifi system, I choose to play a vinyl record on my old Thorens TD-165 instead of a CD. It’s not about what kind of music to listen to, it’s just about listening to a vinyl record: unfolding it, cleaning it, letting the stylus descend, they all are gestures of a time gone but that are part of a relaxing ritual which is typical of using a turntable. Playing a CD would be faster, no time lost, but it would be no different from the frantic life of today’s world. What I’m looking for is an escape from this stress: we’re always on the run, so when I have some time to spend listening to music, I’d like to take a break from the frenzy. Preparing to listening to a vinyl record takes time – and this is just the point.

For the same reason I thought about starting a semi-commercial activity: restoring old turntables like mine and enjoy the hand work needed to eliminate the small defects due to aging; then I would resell the product, taking advantage of the vinyl resurgence of the last years. Where’s the dilemma? My own Thorens TD-165 was given to me by a friend who did not use it. It was the basic model of the brand’s production in the 70s, it was the cheapie. The top of the line was then the TD-160, more expensive still today and also widely considered still worth of high-level modern hifi systems. If I’ll be servicing old Thorens TTs, the TD-160 will sure be one of the models to focus on. But how could I work on one of them for weeks only to part from it without ever thinking about keeping one for myself?

The greatest portion of the dilemma is due to the fact that the TD-165 I have at the moment belonged to the late father of a friend of mine. When his father passed away in the early 80s, his son was not comfortable with using his belongings. The Thorens was one of those things he was jealous of. It took some time before I could see it being played at parties. Then, digital came in and that friend of mine bought his first CD player. The turntable was slowly being moved to the background. I often asked him to make a price, but then I saw the TT thrown in a locker. So I told him that if it had to be treated that way it would have been better at my home. So today, after all the fixes I did, after all I learned on suspended turntables, how can I resell it and replace it with a superior model? I can’t certainly afford to keep two turntables at home (no room and no money), so if I keep the TD-160, the TD-165 must go. The TD-160 I’ve found is a bargain. It’s even close to home (shipping suspended turntables may be a nightmare) and it looks like its in very good conditions. How can I miss this chance?

My ethics would restrain me: I shouldn’t be spending money on a turntable since I already have one, which I serviced well and is still working good (some believe the sonic differences between the two units are almost intangible); furthermore, on the very rare occasions that friend of mine comes to visit, he takes a quick look to the old Thorens his father owned, happy to see it functioning so well (although he would never dream of using it today). How can I say next time that I sold it to buy a better one?

Actually, chances are he wouldn’t even notice. Aesthetical differences are few. But the point is I do know it. Am I exaggerating? Am I being contorted? Maybe this friend of mine couldn’t care less of an old turntable. A good Thorens TD-160 has far more value today than a TD-165. It would be a good chance for adding a good unit to my system.

T

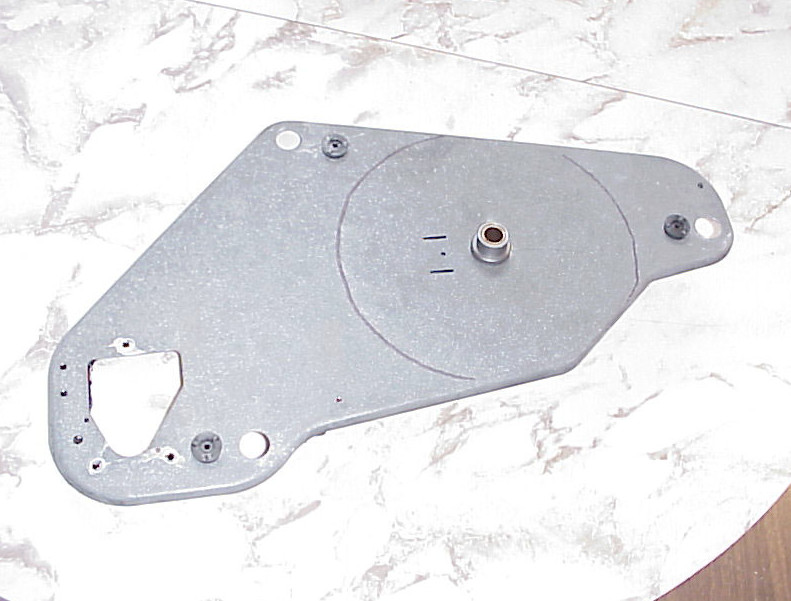

T he two turntables have small differences: the TD-165 has a plastic resin subplatter (side, at right), the TD-160 has a metal one. It is generally believed that the TD-165 subplatter has a 7 mm diameter bearing shaft, while the TD-160’s is 10 mm. Yet, some TD-165 like mine have a 10 mm bearing shaft, although the subplatter is still resin. This is the main difference between the two. Some believe this is fundamental for the final sonic result, since the shaft’s thickness affects the quality and the stability of rotation and a 10 mm shaft will improve the wow & flutter performance.

he two turntables have small differences: the TD-165 has a plastic resin subplatter (side, at right), the TD-160 has a metal one. It is generally believed that the TD-165 subplatter has a 7 mm diameter bearing shaft, while the TD-160’s is 10 mm. Yet, some TD-165 like mine have a 10 mm bearing shaft, although the subplatter is still resin. This is the main difference between the two. Some believe this is fundamental for the final sonic result, since the shaft’s thickness affects the quality and the stability of rotation and a 10 mm shaft will improve the wow & flutter performance.

The TD-160 motor is also more advanced (at right): a pulley with friction to help to start and stop (at right) vs. a simple plastic pulley (at left). The plinth is identical (the TD-160 chassis is generally more resistant and its plinth is real wood vs. vinyl veneer), everything alse is identical. It’s not easy to understand why the TD-160 performance should be much superior to the 165’s. My reference online journal, TNT-Audio, believes (its editor does) that the TD-160 deserves top-level systems, while the TD-165 is not much worth the efforts I did to improve its performance. Others can’t hear much sonic differences, they are there but nothing serious. Other Thorens experts such as Vinyl Nirvana and Stefano Pasini, believe I still have a good system going. So what do I do?

Once I was convinced that, in order to install a subplatter from a TD-160, I should have replaced the subchassis too, because of the 10 mm vs. 7 mm shaft (at left). It’s a bit complicated but still doable. Then I discovered that some TD-165s like mine have a 10 mm shaft. So I could install a zinc subplatter and I would have a TD-160 inside and the old friend’s TD-165 outside. I could even think to replace the motor pulley one day. Actually, I tried that but the TD-165’s springs would not support the additional weight of a zinc subplatter – not in my model which has transport lock blocks that prevent the subchassis from floating too low (this would be possible in other models with no transport locking system).

The other big difference is the tonearm: the TD-165 is equipped with a TP-11 tonearm using an antiskating system based on a threaded weight (below, at left); on the TD-160, the TP-16 tonearm has a magnetic system (below, at right).

Maybe the more advanced TP-16 is really the best. It allows for a dynamical adjustment of the VTF, impossible on the TP-11. For the rest the two tonearms are identical, counterweight excluded. Both are considered not really good, nothing bad though, but it would be better to replace them one day. Therefore this is not the issue..

Maybe the more advanced TP-16 is really the best. It allows for a dynamical adjustment of the VTF, impossible on the TP-11. For the rest the two tonearms are identical, counterweight excluded. Both are considered not really good, nothing bad though, but it would be better to replace them one day. Therefore this is not the issue..

At face value, the mechanical differences of these two turntables wouldn’t justify their price difference: 100-200 euros maximum for the TD-165 versus 250-400 (or even more) for a TD-160 (I’m talking about stock turntables, with no one of the adjustments usually performed on them).

So what? I’m tempted to resell the TD-160 to get more money out of it. But my passion for vinyl sound and for this kind of Thorens turntables (those from the early 70s, not the various MKIIs) would convince me to keep the beautiful TD-160, sentimentalisms aside. Otherwise I wouldn’t lose much in keeping the TD-165, which, with the right modifications, would fill the gap with time…

Now enjoy this nice video by the great Dave Archambault from Vinyl Nirvana comparing the two historical turntables: